We get asked a lot of questions about R/C wheels, tires, and foams. There is a lot of good info out there on forums and social media that can be helpful. Some articles will leave you with more questions than answers. In this article, we will go over some tips and tricks for selecting the proper set-up for your scale R/C vehicle. There are numerous variables to consider when selecting a new wheel, tire, and foam package. The scale R/C scene is still gaining in popularity and because of that, there are almost endless options to choose from in the aftermarket R/C world. It all comes down to what do you need and how much do you want to spend? Let’s dig in and go over the basics!

Where do we begin? Let’s break it down by each individual component, wheels, tires, and foams. Here you can see just a fraction of what is available for the scale R/C market.

The photo below shows the three most popular wheel and tire sizes: 1.55 on the left, 1.9 in the center, and 2.2 on the right. There are numerous different tire diameters and tread patterns for each wheel size too. When replacing your stock tires, it is usually best to keep the new tires similar in diameter to your old ones, otherwise the tires may rub the body or chassis. If there is a big enough change in tire diameter, a gearing or motor change may also be required in order to prevent electronics from overheating.

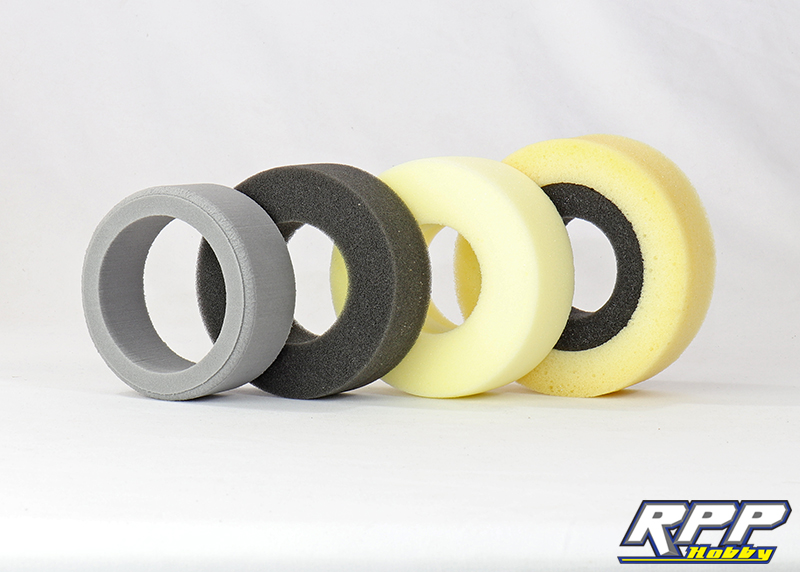

Foams are another “can of worms” if you are not sure what is best for you. Pictured below are the four most common tire foams used in scale R/C cars and trucks. From left to right: closed cell foam, open cell foam, memory foam, and dual stage foam. All have their purpose in the R/C world. Closed cell foams are usually firm, water resistant, the most resilient over time, and usually the most expensive. Open cell foams are the most commonly used foams. Almost all RTR vehicles and replacement tires supply these foams in the package, and they are inexpensive to replace. Memory foams are slightly heavier than the rest and as the name suggests it retains memory for a few seconds before returning to its original shape. These foams work great in the rocks to help prevent tire hop on steep climbs, but they can be temperature sensitive. In the cold they have a tendency to get firmer, and in the heat they will get softer. Dual stage foams are made up of two different foams, with different foam densities. Usually the center core is really firm and the outer foam is softer. People use these for a little extra sidewall support in off camber situations to prevent the tires from folding over.

Let’s talk wheels! There are endless popular wheel choices to choose from, from numerous manufacturers, when it comes to upgrading. Glue-on wheels and beadlock wheels are your two choices. Glue-on wheels are the cheapest of the two, are usually made of plastic, and your tires are glued directly to the bead seat. Beadlock wheels are offered in plastic, aluminum, and steel. These wheels clamp down on the tire beads with screws to hold them in place. The best thing about beadlock wheels is they are reusable. The wheels can be taken apart so new tires or foams can be installed. Plastic beadlocks are usually the cheapest option, but metal wheels are becoming more affordable depending on what you are looking for. Plastic beadlocks do have a tendency to strip out the screw holes over time, so it is best not to over tighten the ring screws during installation.

Time for some tire talk! There really are an endless amount of choices for tires out there today, from mild to wild. 1.55 tires, are usually for the smaller scale builds that have a daily driven appearance. 1.9 tires are usually for the true 1/10th scale builds that have an aggressive off road look yet still could be seen on the road. 2.2 tires are usually for the rig that gets trailered to the off road park, unloaded, and severely beat on. It really depends on what the end user has for a vehicle, and what they want out of it. Here you can see a 1.55 tire on the left, 1.9 center, and 2.2 on the right for size comparison.

To breathe, or not to breathe? That is the question. Most people will vent their tires or wheels so air can escape when the tire is compressed. This usually helps greatly with traction and forward bite. Some people vent the wheels as shown in the first photo. Some will punch a small hole, or two, in the tire’s inner sidewall or tread as shown in the second photo. If you buy a new set of wheels and they already have vent holes you will be good to go. If you buy wheels that don’t, like most aluminum beadlocks, you may have to find a way to vent your tires. A hole punch is a good way to do it. Usually one or two small 1/8th inch holes are enough to get the job done. That being said, you will find people that run their wheels and tires with no vent holes at all. Enthusiasts that drive in mud and water constantly may not vent their wheels to keep water and debris from collecting inside the tires. Only drawback here is if you change altitude to go crawl a new location the tire will swell up as you gain elevation, or shrink if you descend.

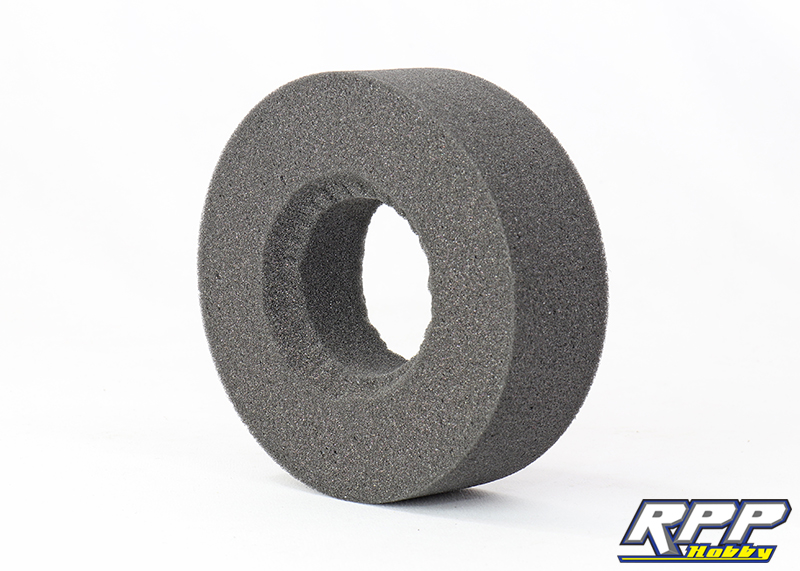

Tuning foams? It is possible to modify the feel of tire foams with some crafty trimming. It is fairly easy to soften the feel of a foam with an sharp hobby knife by cutting a grid pattern in the face of the foam as pictured below. Try not to go too deep with your cuts or you risk ripping your foam when installing or removing it from your tire. A tighter cut pattern will soften the foam up even more. This allows the individual squares of the foam to flex separately instead of as a whole.

When mounting a wide foam, it can be tough to tuck the bead of the tire into the bead seat of the wheels. A little trimming with curved Lexan scissors on the inner diameter of the foam allows the tire’s bead to sit properly for easy mounting.

Our personal preference, when it comes to scale rock crawling, is a nice firm foam that is slightly smaller than the inner diameter of the tire’s carcass. This allows the tread of the tire to spread out for better traction while providing good sidewall support for off camber situations. It also nicely mimics a 1:1 tire that has been aired down for off road use.

That brings us to the end of our scale tire, wheel, and foam blog. Hopefully you found the information useful. It is a lot to cover, and take in, but over time you will see what works best for your rig and the terrain you frequent. As always, thanks for checking out the RPP Hobby Blog!

Trx4-sport with the portal’s. What wheals fit? If the back part of the rim is too narrow they don’t fit. What wheals do you have that fit with the portal’s?

We know for sure the Pit Bull aluminum beadlock wheels clear the portal hubs. Most of the Vanquish wheels should clear too, with the right hub width.